Industries

Applications

Cookie Consent

Cookies are used for statistical purposes and to improve the site.

Cookies will be used after you click "Accept" or if you continue using Dynisco.com

To find out more please review our Privacy Policy.

.JPG)

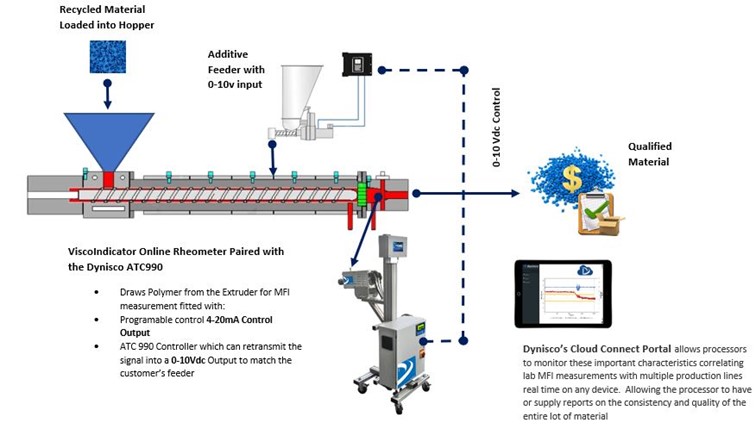

Increase the amount of recycled material that can be used without impacting material quality

Learn More

Dive into the intricacies of the melt flow index (MFI), its significance in polymer science, and how Dynisco's advanced indexers optimize polymer processing.

Learn More

Explore the differences between viscosity and intrinsic viscosity, crucial concepts in fluid dynamics, and their impact on scientific research

Learn More

Material analysis solutions range from the analysis of a polymer in the laboratory, to online quality control in production, to processing small quantities of special polymers or composites. Check out this Q & A blog to learn more about inline viscosity measurement in PET and polyolefin recycling.

Learn More

Dynisco recently helped a pharmaceutical company in the characterization of their new formulation product using our LCR7000 Capillary rheometer. Continue reading to find out more....

Learn More

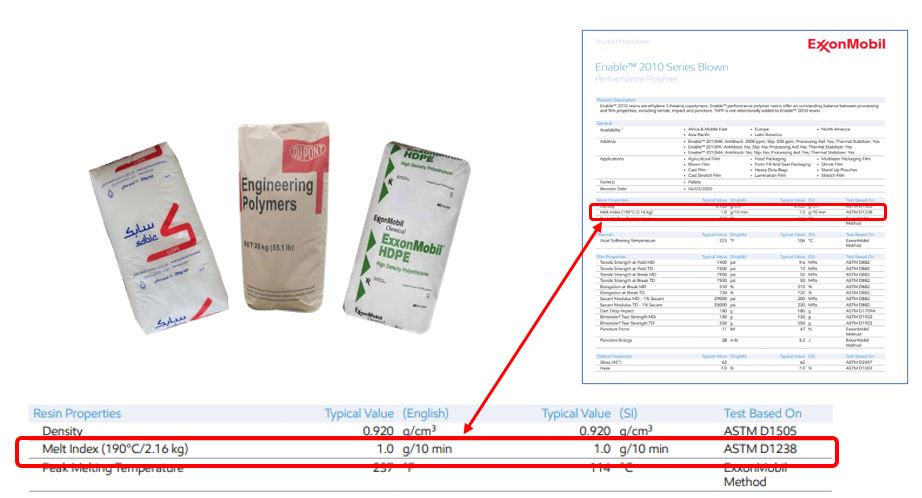

In this article we explain the importance of a stable MFI and how this can be done automatically.

Learn More

For melt flow rate testing above 1000g/10min, our LMI5000 and 5500 series melt flow indexers can utilize Procedure C testing with a "half-die" capillary to measure the melt flow rate of low viscosity polymers.

Learn More.jpg)

Our line of Fluidized Temperature Bath’s (FTB) liquid-like properties provide fast heat transfer to immersed tooling for immediate heating and burning off tough-to- clean polymers.

Learn More

Understand how to increase the amount of recycled material that can be used without impacting material quality

Learn More

Who in the Lab is ready to stop cutting prep-stock samples with scissors & shears by hand?

Learn More.jpg)

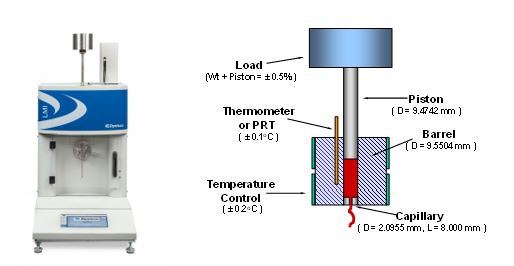

One of the common classical assumptions in rheological analysis, particularly in polymer melt flow in capillary rheometers, is no-slip boundary condition. Read more on why is it important to understand wall slippage when using a capillary rheometer for rheological analysis?

Learn More.JPG)

Providing automated access to pressure and temperature readings from your extrusion line makes complete sense to any polymer transforming operation.

Learn More.JPG)

How to properly charge the barrel before starting a test in LCR capillary rheometer

Learn More.jpg)

The following instructions will assist with the installation of LABKARS software (version 3.92) on Windows 10 operating systems.

Learn More_288x178.jpg)

Dynisco online rheometers can be easily installed in variety of extrusion lines and continuously measure the intrinsic viscosity parameters of the extrudates during an extrusion process.

Learn MoreThe following instructions will resolve the key violation error that appears in Labkars software, which is used to control our LCR7000 series capillary rheometers

Learn More.jpg)

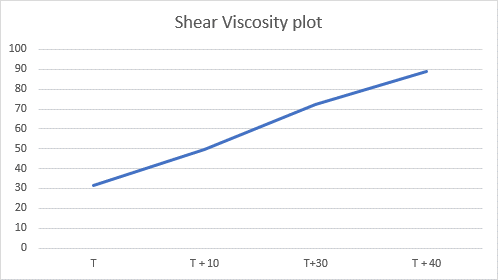

Flow curves of polymer melts (the graph of viscosity versus shear rate in the log-log scale) has two distinct behavior of Newtonian and Power law. At very low shear rates the Newtonian behavior dominates where the viscosity is independent of the shear rate and it approaches the value of η_0 which has been named as the zero-shear viscosity

Learn More.jpg)

A thermal stability test can determine the resistance of a polymer melt to a change in the molecular structure at the test temperatures. The results of this test depend on the temperature, residence time at that temperature, material formulation, presence of moisture and/or contaminates

Learn More

In this blog our Rheological Scientist, Azadeh Farahanchi Ph.D. discusses how to understand plastic shear thinning behavior using a melt indexer

Learn More.jpg)

Method A/B is a test that can be performed in a melt flow rate tester in order to calculate the value of the polymer`s melt density at a specific temperature

Learn More

This blog talks about the various methods (Method A and B) and their differences in measuring the melt flow rate of plastic material

Learn More_288x190.jpg)

Die swell has been used as a qualitative measure of polymer melt elasticity for quality control purposes in plastics industry. Die swell also can be used for analysis of extrudate smoothness in an extrusion process.

Learn More.jpg)

One of the key factors in any MIM process is the flow behavior of the feedstock during filling of of the mold. In order to have a defect free molding process (without jetting, short shot, sink mark, crack, etc.) with desired mechanical strength (tensile, flexural, failure stress, etc.) in the final products, understanding of the rheological properties of the binder and feedstock is necessary

Learn More

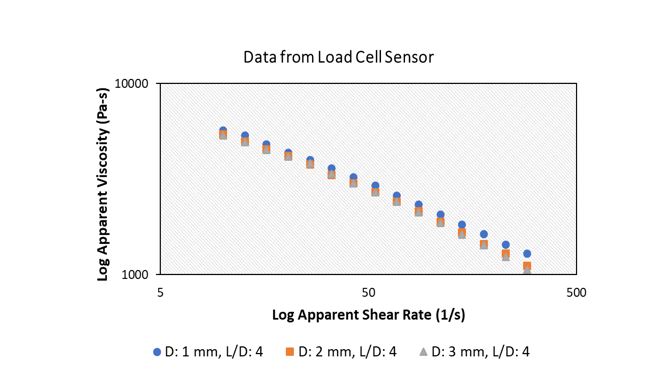

Capillary rheometers are one of the most common types of analytical devices, used to analyze the flow properties of viscoelastic polymer materials under processing conditions. The Dynisco LCR7001 can utilize both load cell and pressure transducer simultaneously in order to produce information on both the force applied to the polymer sample and the resulting pressure at the die entrance.

Learn More

Online rheometers have been used increasingly in plastics processing and recycling industry to provide continuous data stream of rheological properties and real-time information on an extrusion process. This can beneficial for controlling of in-process product quality, reducing of waste stream, and increasing of process efficiency

Learn More

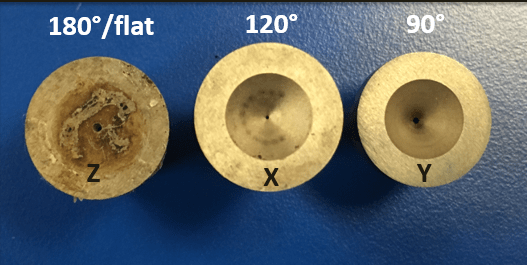

Gain an understanding about the selection of capillary rheometer dies that Dynisco produces for various applications.

Learn More

Nowadays, composites are ubiquitous in many parts of modern societies such as constructions, textiles, nonwovens, and automobile industry. In composites, interface plays a pivotal role in final mechanical properties.

Learn More

Creating a flowing material can be measured in grams per ten minutes (per the ASTM D1238/ISO 1133) providing vital material properties.

Learn More

It can be very difficult, if not impossible, to achieve complete indentification of most polymer products. However, in most cases, this is usually not needed; what is needed is the separation, or identification, of numerous molding materials whose identity has been lost, or an indication of the type of material used to create a component.

Learn More

38 Forge Parkway,

Franklin MA 02038

+1 508 541 9400

Pfaffenstr. 21, 74078,

Heilbronn, Germany

+49 7131 297 0

Lot 3615, Jalan SM 6/8

32040 Seri Manjung, Perak, Malaysia

+605 6884014