Industries

Applications

Cookie Consent

Cookies are used for statistical purposes and to improve the site.

Cookies will be used after you click "Accept" or if you continue using Dynisco.com

To find out more please review our Privacy Policy.

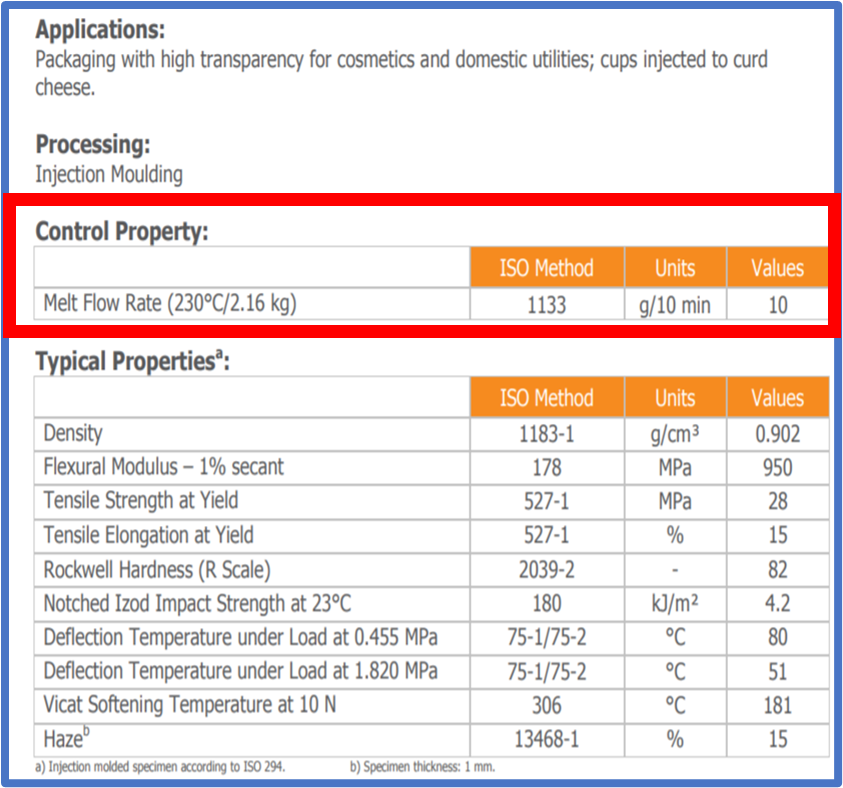

Polymer science is a complex field. It covers a breadth of quantitative and qualitative approaches to materials analysis and is replete with intricate jargon. One central concept that may be prone to misconception is the melt flow index (MFI). MFI is simply a measure of material output, and not an important value that can be used in production or quality control. This is a measure of how easily a thermoplastic melt will flow. But it neither gives a direct expression of molecular weight nor viscosity. Rather, the melt flow index is an empirical value that ultimately depends on test conditions. So, what makes it important?

that may be prone to misconception is the melt flow index (MFI). MFI is simply a measure of material output, and not an important value that can be used in production or quality control. This is a measure of how easily a thermoplastic melt will flow. But it neither gives a direct expression of molecular weight nor viscosity. Rather, the melt flow index is an empirical value that ultimately depends on test conditions. So, what makes it important?

This article delves into the intricacies of MFI, elucidating its significance, measurement techniques, and relevance in the polymer industry.

The melt flow index is often abbreviated as MFI or the melt flow rate (MFR).The quantifiable measurements are expressed as grams per 10 minutes (MFR), grams per cubic centimeter (MVR) and melt density. While this test method does not compute viscosity, MFR and MVR can be correlated to viscosity. In simpler terms, it gauges the materials ability to flow under specific temperature and force conditions. It defines the mass of a polymer, which is used to determine the material output in weight over time. The force used in the melt flow test is exerted through predetermined weights at specific temperatures listed in the relevant test standards.

MFI serves as a critical indicator for those involved in the processing of thermoplastics. It offers insights into many key factors, including:

The melt flow index offers invaluable insights for plastics processors and recyclers, ensuring that the quality of the end product remains consistent. Moreover, understanding the MFI is instrumental in optimizing the processing conditions, thereby ensuring efficiency and quality in production.

MFI is precisely measured using a specialized laboratory instrument called a melt flow indexer. This instrument meticulously maintains a designated temperature range. Concurrently, it employs a consistent weight load to extrude the material through a capillary. An example of such sophisticated equipment is the Dynisco LMI5500 Melt Flow Indexer.

An example of such sophisticated equipment is the Dynisco LMI5500 Melt Flow Indexer.

The determination of MFI is not a one-size-fits-all approach. Various test methods exist, with ASTM D1238 being a prominent standard. This method is widely recognized and adopted for its accuracy and reliability in measuring thermoplastic melt volume flow rate.

An interesting facet of MFI is its indirect correlation with the molecular weight of the polymer. Typically, a higher MFI indicates a lower molecular weight and vice versa. This relationship is crucial as the molecular weight can influence various properties of the polymer, from its mechanical strength to its processing behavior.

In the ever-evolving domain of polymer science, understanding and accurately measuring the melt flow index remains a cornerstone. Dynisco manufactures state-of-the-art laboratory melt flow indexers for those who seek precision, reliability, and industry-leading technology when performing critical testing of polymer behavior. Explore the legacy and innovation of Dynisco's Melt Flow Indexers and elevate your polymer processing endeavors.

Laboratory Mixing Extruder as Spinning Tool to Fibrillate Droplet Phase of Polymer Blend Systems

Correlation of Melt Viscosity of Polyethylene Terephthalate to Solution Intrinsic Viscosity

Characterizing Thermal Stability of Polymer Melts Using a Capillary Rheometer

38 Forge Parkway,

Franklin MA 02038

+1 508 541 9400

Pfaffenstr. 21, 74078,

Heilbronn, Germany

+49 7131 297 0

Lot 3615, Jalan SM 6/8

32040 Seri Manjung, Perak, Malaysia

+605 6884014