Industries

Applications

Cookie Consent

Cookies are used for statistical purposes and to improve the site.

Cookies will be used after you click "Accept" or if you continue using Dynisco.com

To find out more please review our Privacy Policy.

Melt Flow Index- An Important Aspect of a Plastics Sustainability Initiative: Increasing the amount of recycled material that can be used without impacting material quality

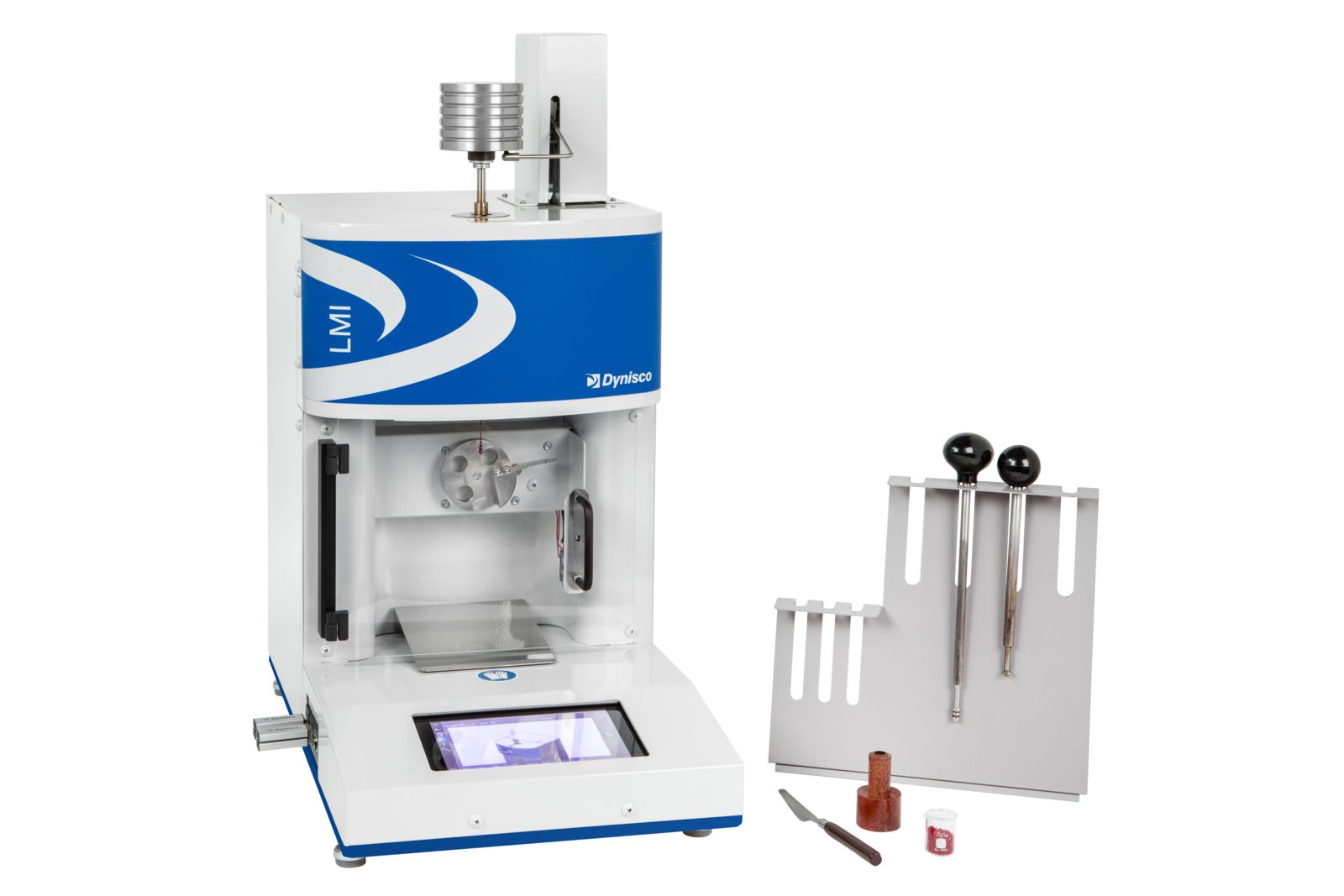

A Melt flow Indexer, is a laboratory instrument that provides a plastics processor or recycler valuable information that either confirms a polymer’s specification on a polymer data sheet or in the case of recycled material, informs operators of the current Melt Flow Index (MFI) or Intrinsic Viscosity IV of the recycled plastic.

So, the questions most often asked is “How can I use the information provided by this instrument in the daily operation of my plant?”

Step 1: Review the Target Specification of the Polymer

When looking to insert recycled material into your process, it is important to start at the beginning… Verify what the polymer should be on the Specification Sheet

Step 2: Take a sample (or samples) of the material granulated out of the gaylord

To ensure the quality of each gaylord of material, you can take a sample (or few samples) of each gaylord and quickly test them and get the MFI of the sample(s) actual melt flow index in g/10min

Step 3: Mark or record the actual Melt Flow Index

Step 4: Adjust your blender or feeding system

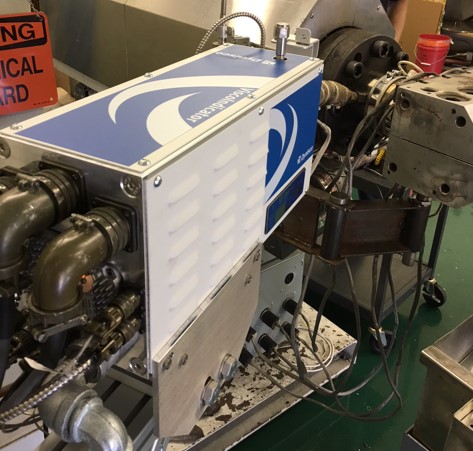

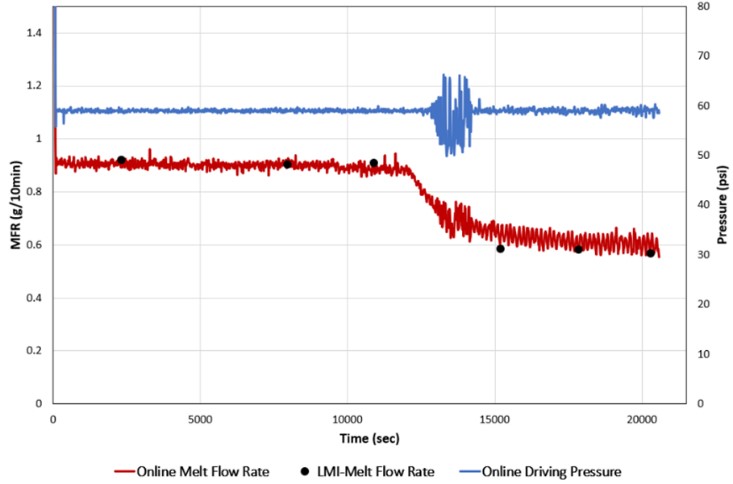

For those using extruders, you can easily take the next step adding a Dynisco Online ViscoIndicator to your standard extruder that enables full lot to lot measurement of your production run while giving you the ability to send an automatic signal to your blender or feeder for real time adjustment to your production line.

This data can be correlated to your melt flow indexer for conformation that the polymer used in your process meets the standards you have set.

Don’t forget… all these test samples can be uploaded to the Dynisco IoT Cloud Connect where your polymer data can be stored and compared by device, production run, operators, and global locations. By phone, tablet, or PC.

Using Dynisco’s ViscoIndicator to Control Polymer Additives in the Extrusion Process

Melt Flow Index- An Important Aspect of a Plastics Sustainability Initiative

38 Forge Parkway,

Franklin MA 02038

+1 508 541 9400

Pfaffenstr. 21, 74078,

Heilbronn, Germany

+49 7131 297 0

Lot 3615, Jalan SM 6/8

32040 Seri Manjung, Perak, Malaysia

+605 6884014