Industries

Applications

Cookie Consent

Cookies are used for statistical purposes and to improve the site.

Cookies will be used after you click "Accept" or if you continue using Dynisco.com

To find out more please review our Privacy Policy.

Explore key melt pressure technologies—from strain-gauge to fill-free sensors—improving safety, accuracy, and compliance in polymer processing.

Learn More.png)

Explore the essentials of accurate melt-pressure measurements for material characterization in extrusion. Discover Dynisco's commitment to precision.

Learn More

Dynisco designed the cleaning tool kit for use in removing excess plastic from 1/2-20 UNF mounting holes for pressure and temperature transducers, burst plugs and thermocouples

Learn More.png)

Quickly and accurately check pressure transducers in the field with our PPS1100 portable pressure source

Learn More.JPG)

Explore the relationship between a pressure sensor, and the dedicated indication device or controller, specifically when it appears the pressure reading is not reading correctly, and is causing issues with the process

Learn More.jpg)

Learn how Dynisco sensors are designed to withstand contaminants within the recycling process

Learn More

If temperature changes during your process or re-zeroing the pressure at start up is ever an issue, the Dynisco™ SPX-T Series of pressure sensors is the ideal solution. Check out this blog to learn more

Learn More.jpg)

Dynisco pressure transducers are widely used in complex and specific applications but sometimes the need to be fulfilled is very simple: measuring pressure and give an alarm in case of overpressure

Learn More.jpg)

In this blog, we will explore the unique feature known as “R-Cal” which is a standard for the majority of the Dynisco pressure sensor product offering.

Learn More

What is HART Communication Protocol and what are the benefits of HART when buying an SPX or Vertex sensor? Learn more about the benefits of choosing HART are Digital Capability, Analog Capability, Interoperability, & Availability

Learn More.jpg)

Wonder how to choose the right sensor for your application needs? Check out this blog to better understand what specifications help determine you ideal sensor.

Learn More_228.jpg)

Dynisco sensors and instrumentation are primarily used as safety lockout system, which will prevent over pressure conditions in extrusion and injection molding processes, by interrupting the power source to the equipment.

Learn More

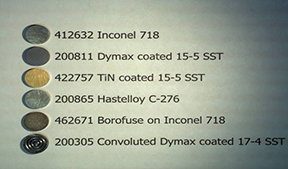

The selection of diaphragm material used on the Dynisco pressure sensor, depends on the application where the sensor will be used. We must first ask the question, does the sensor come in contact with a pure material, or a blend of materials?

Learn More

Find the causes and solutions for common sensor problems.

Learn More

After investigating these spikes, we developed a laboratory method for determining the magnitude of the actual pressure spike that caused a specific field failure. The method shows that pressure spikes many times that of nominal system pressure can occur in a system

Learn More

The signal output from a melt pressure transducer used in plastic extrusion and injection molding should be calibrated with instrumentation. This is vital to the accuracy and reliability of the pressure measurement.

Learn More

Why is Mercury Used in Melt Pressure Sensors? A transducer is an electronic device that converts energy from one form to another. In the case of a Dynisco pressure transducer, the process fluid exerts a pressure force on a thin flexible metal diaphragm at the tip of the sensor.

Learn More

38 Forge Parkway,

Franklin MA 02038

+1 508 541 9400

Pfaffenstr. 21, 74078,

Heilbronn, Germany

+49 7131 297 0

Lot 3615, Jalan SM 6/8

32040 Seri Manjung, Perak, Malaysia

+605 6884014