Industries

Applications

Cookie Consent

Cookies are used for statistical purposes and to improve the site.

Cookies will be used after you click "Accept" or if you continue using Dynisco.com

To find out more please review our Privacy Policy.

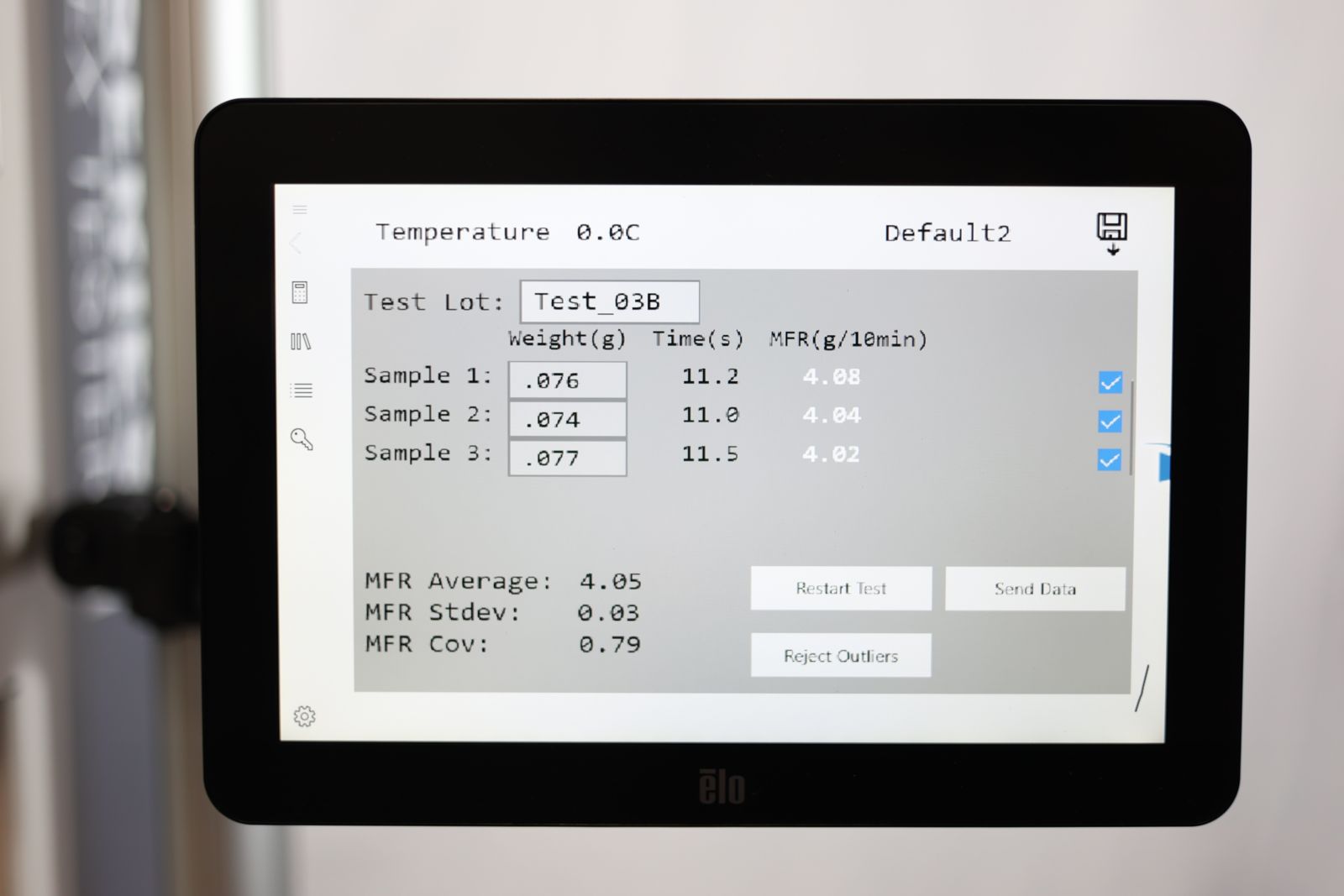

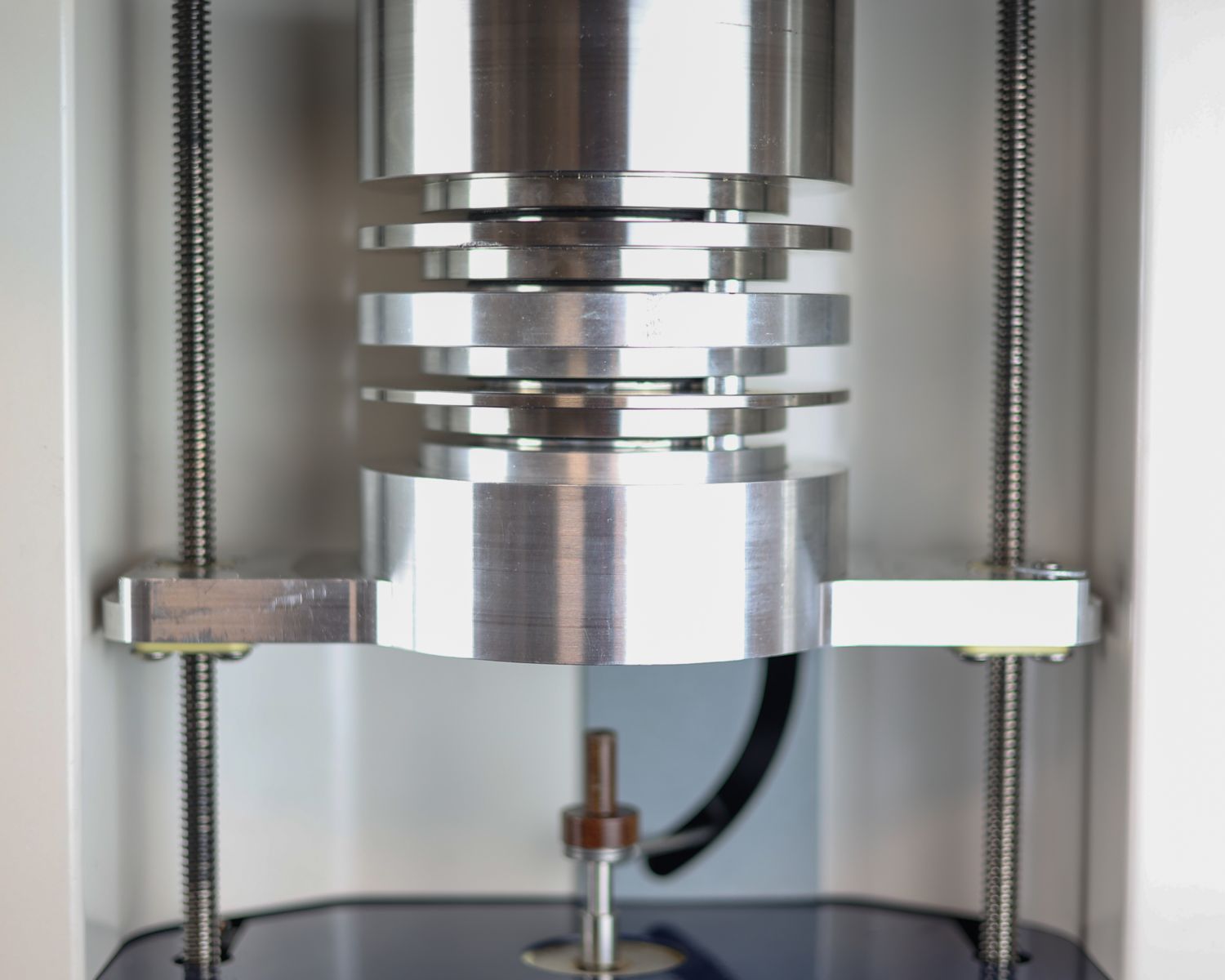

With step-by-step illustrated instructions within the machine’s software, semi-automated test procedures, and several methods to collect test data, the LMI6000 makes it easier than ever to verify your materials before they enter your process. The LMI6000 can perform ASTM testing methods A, A/B, B, C, and D (D is only avalable with auto-lift model), and can measure intrinsic viscosity [IV] through an altered procedure of test method B. The optional automated lift system allows you to let the machine run most of the test procedures unattended after you pack a small sample of material into the machine’s barrel.

Whether you’re a manufacturer, recycler, material researcher, or quality control expert, the LMI6000 plays a critical role in ensuring your material meets the proper specifications before it enters your process. Melt flow rate (MFR), melt volume rate (MVR), and intrinsic viscosity (IV) are critical markers for determining how your material will behave inside your industrial process and within the finished product. These properties are invisible to the naked eye and can vary from the material’s printed specification. With the help of the LMI6000, you can verify that your material meets your standards for quality and trace changes in material characteristics between each lot of polymers.

The LMI6000 marks a new generation in accessibility, as well as automation. With a new electromechanical lift system, tests can now be run without manually lifting weights, allowing for simultaneous test runs between multiple machines. The auto lift also increases operator safety and improves test accuracy. The dedicated power switch also ensures that the LMI is shut down safely, saving data before cutting the power. With the larger and adjustable touchscreen interface and color display, the upgraded hardware architecture, and software automation, the LMI6000 is convenient as ever.

38 Forge Parkway,

Franklin MA 02038

+1 508 541 9400

Pfaffenstr. 21, 74078,

Heilbronn, Germany

+49 7131 297 0

Lot 3615, Jalan SM 6/8

32040 Seri Manjung, Perak, Malaysia

+605 6884014