Industries

Applications

Cookie Consent

Cookies are used for statistical purposes and to improve the site.

Cookies will be used after you click "Accept" or if you continue using Dynisco.com

To find out more please review our Privacy Policy.

Processing material in the Dynisco Melt Flow Indexer is an easy and relatively quick process. It is however, important to remember to thoroughly clean out the barrel, piston and die in between each test. Residual material can be left in the barrel and the orifice of the die that will continue to cook at the temperature you have the unit set at and degrade. In addition, the material can and will contaminate subsequent tests. The steps in cleaning you Melt Flow Indexer are simple. Please use the items found in the Dynisco LMI Tool Cleaning Kit (PN D5000-TOOL). A complete list of items can be found on the attached brochure provided.

After running a sample conduct the following and please be mindful that you are working with an extremely hot instrument so please wear your protective eyewear and gloves during this process:

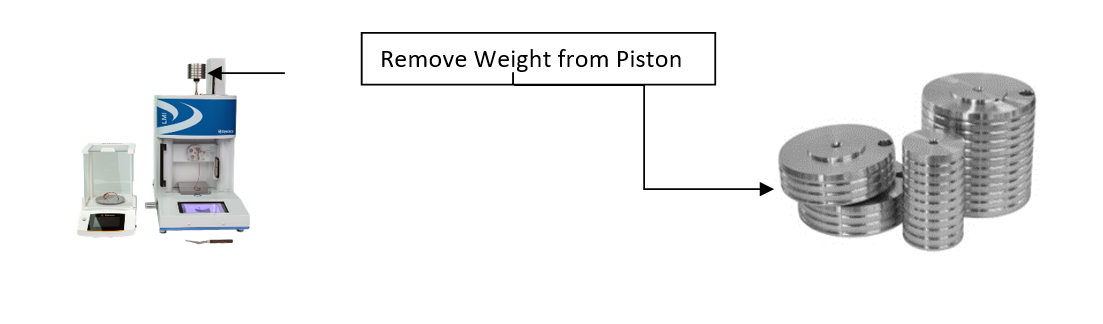

1. Remove the weight from the piston and set aside carefully,

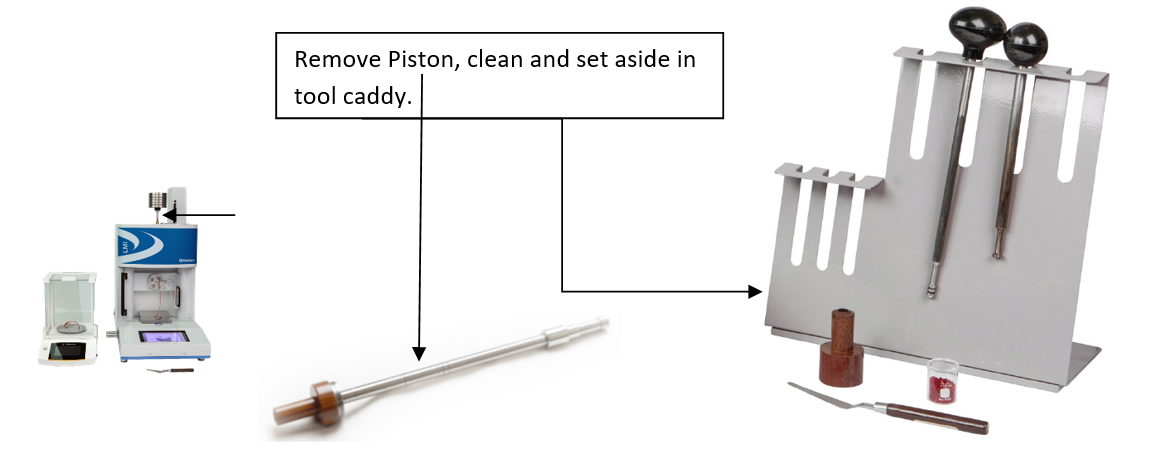

2. Remove the piston from the barrel and wipe it off completely while it is warm.

3. Remove the Die with the Orifice Removal Tool (PN 0051-35) and clean it while it is warm. Remember to not only on the surface, but use the Pin Vice (PN 0051-38) and/or the Orifice Brush (PN GP0310) to remove any residual plastic left in the center orifice as well. Pictures shown below.

4. Clean the Barrel of the Dynisco Melt Flow Indexer with the Barrel Cleaning Tool (PN 0051-40) and Cotton Patches (2-3 times). If you need additional scrubbing of the barrel, use the Bronze Scoring Rod (PN 0051-47) & Bronze Scoring Brush (PN B0555). You can also use an optional Drill/Rod and Brush to speed up the process and provide more vigorous cleaning of the barrel. Those items are optional and can be purchased separatley.

5. Replace the Die in the Barrel and return the Pistol to the Barrel so that the piston stays at the same temperature as the Barrel until it is ready to be used again.

Repeat this process between each test and make it a part of your SOP when using and maintaning your Dynisco LMI. It only takes a few minuets and will keep your results consistent from test to test. For any items needed please contact your local Dynisco Sales Agent or Dynisco Sales Personnel.

Reach the LMI Accessory Catalog here.

Laboratory Mixing Extruder as Spinning Tool to Fibrillate Droplet Phase of Polymer Blend Systems

Correlation of Melt Viscosity of Polyethylene Terephthalate to Solution Intrinsic Viscosity

Characterizing Thermal Stability of Polymer Melts Using a Capillary Rheometer

38 Forge Parkway,

Franklin MA 02038

+1 508 541 9400

Pfaffenstr. 21, 74078,

Heilbronn, Germany

+49 7131 297 0

Lot 3615, Jalan SM 6/8

32040 Seri Manjung, Perak, Malaysia

+605 6884014