Industries

Applications

Cookie Consent

Cookies are used for statistical purposes and to improve the site.

Cookies will be used after you click "Accept" or if you continue using Dynisco.com

To find out more please review our Privacy Policy.

With the global shift in technology away from mercury-based solutions, finding the sensor that's both right for your process and your sustainability initiatives is difficult. It shouldn't be a struggle to find a sensor that excels in your unique process conditions. That's why, at Dynisco, we provide several sensor technologies to cover your specific niche without compromising on performance or capability. Click below to check out our pressure sensors, contact us for more information about our technology options, or continue reading to learn more.

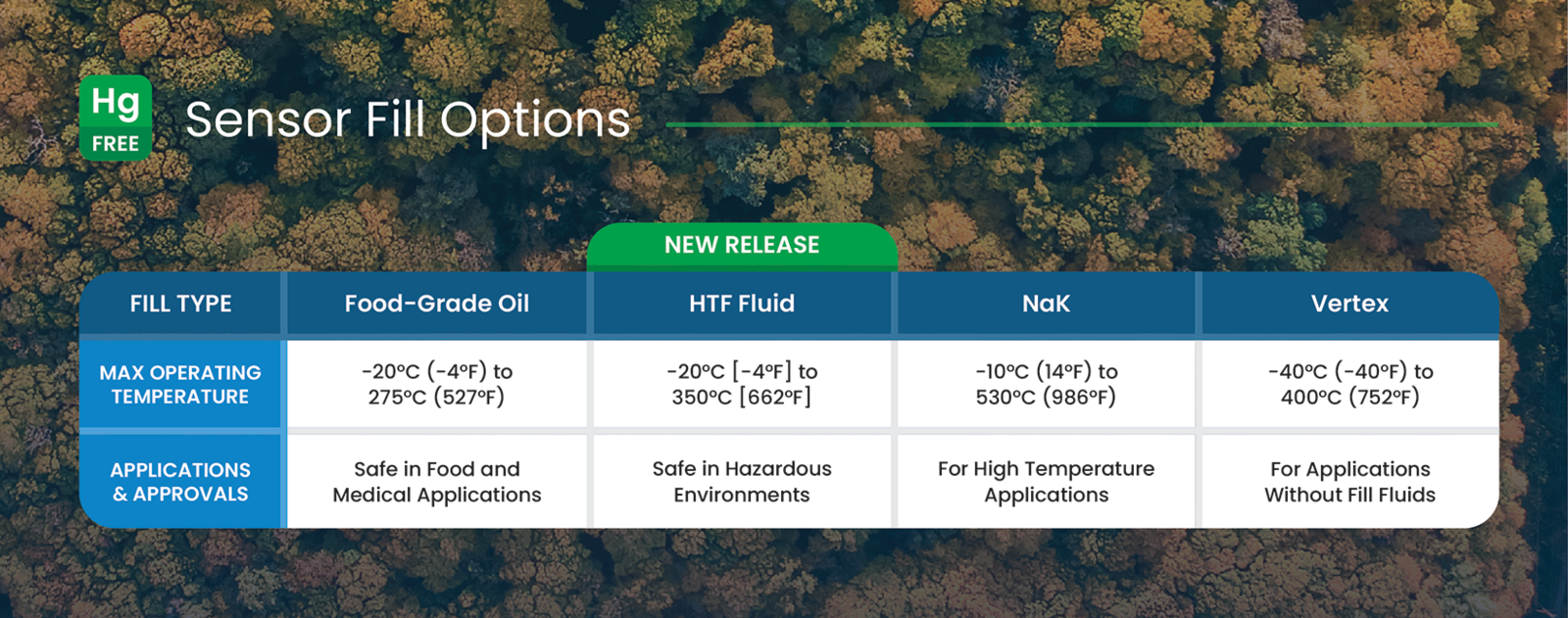

When selecting and configuring your new sensor, you have the option to choose between various fill materials, such as mercury / Hg, NaK, HTF, and food-grade oil. Each option has a different range of pressure and temperature capabilities, as well as differing approvals. In addition, capacitance-based sensors are available as unique models for applications where process contamination is a serious concern. Click below to look at our sensor technology comparison datasheet to help guide your choice.

NAK FILL

The NaK fill, or potassium-sodium fill, option is ideal for the most extreme temperatures, up to 530°C. This fill is both RoHS and FDA-compliant, and can be used in systems in contact with food, medicine, and food / medical packaging. NaK is neither suitable for hazardous environments or ATEX certified.

FOOD-GRADE OIL

The food-grade oil option is ideal for the lower temperatures (less than 275°C) of processes that handle food and medical equipment, or the packaging of food and medicine. This fill is REACH, RoHS and FDA compliant. Additionally, the food-grade oil fill is ATEX certified for both intrinsic safety and explosion resistance.

[NEW] HTF FLUID FILL

The new HTF fluid fill option boasts a 350°C temperature rating, and is ATEX certified for intrinsic safety and explosion resistance. Additionally, HTF is approved for hazardous locations, making it a great alternative to NaK for those who need an ATEX certification and want to transition away from mercury.

CAPACITANCE

Vertex is our capacitance-based sensor series, and offers an impressive 400°C maximum temperature point. Vertex is the only sensor technology approved for both hazardous locations and FDA applications. Vertex is also ATEX certified intrinsically safe and REACH / RoHS compliant.

HG FILL

For hazardous environments not covered by our alternative fill materials, the Hg fill option is available to meet the most demanding process pressures, with a maximum of 30,000 PSI configurable. Hg-filled sensors are ATEX certified for both intrinsic safety and are best suited for industrial applications.

"This is an area for a customer testimonial if we have one. My experience with LMI5500, LCR7500, or ViscoIndicator was great and the quality control on our line has never been better."

Chris Doe, UMass Lowell

FIND YOUR APPLICATION BELOW.

Lorem ipsum...

Lorem ipsum...

Lorem ipsum...

Lorem ipsum...

Lorem ipsum...

Lorem ipsum...

Lorem ipsum...

Lorem ipsum...

Lorem ipsum...

Lorem ipsum...

Lorem ipsum...

Lorem ipsum...

Lorem ipsum...

LCR7500 SERIES OPERATIONAL OVERVIEW

OVERVIEW OF CAPILLARY RHEOMETER TESTING PROCEDURES

The LCR7500 series of capillary rheometers offers many new features and maintains the highest possible level of test accuracy and repeatability. In this video, we demonstrate an overview of the testing procedures of the LCR7500, including test setup, running, cleaning, and saving test data. Specifically, we are running a steady state test to study the stable shear viscosity of the material over certain shear conditions. This test helps identify the viscosity changes into numerous industrial applications of injection molding, extrusion process, blow molding, and so on.

GLOBAL SUSTAINABILITY

INITIATIVES

GLOBAL SUSTAINABILITY INITIATIVES

Increased demand for recycled materials in polymer production means higher variability of raw materials and greater risk of degradation.

GLOBAL RIGHTSHORING

INITIATIVES

GLOBAL RIGHTSHORING INITIATIVES

With production facilities around the world getting materials from multiple suppliers, product quality and consistency is harder to control.

Dynisco ©2023. Contact your local sales representative for more information.

38 Forge Parkway,

Franklin MA 02038

+1 508 541 9400

Pfaffenstr. 21, 74078,

Heilbronn, Germany

+49 7131 297 0

Lot 3615, Jalan SM 6/8

32040 Seri Manjung, Perak, Malaysia

+605 6884014