Industries

Applications

Cookie Consent

Cookies are used for statistical purposes and to improve the site.

Cookies will be used after you click "Accept" or if you continue using Dynisco.com

To find out more please review our Privacy Policy.

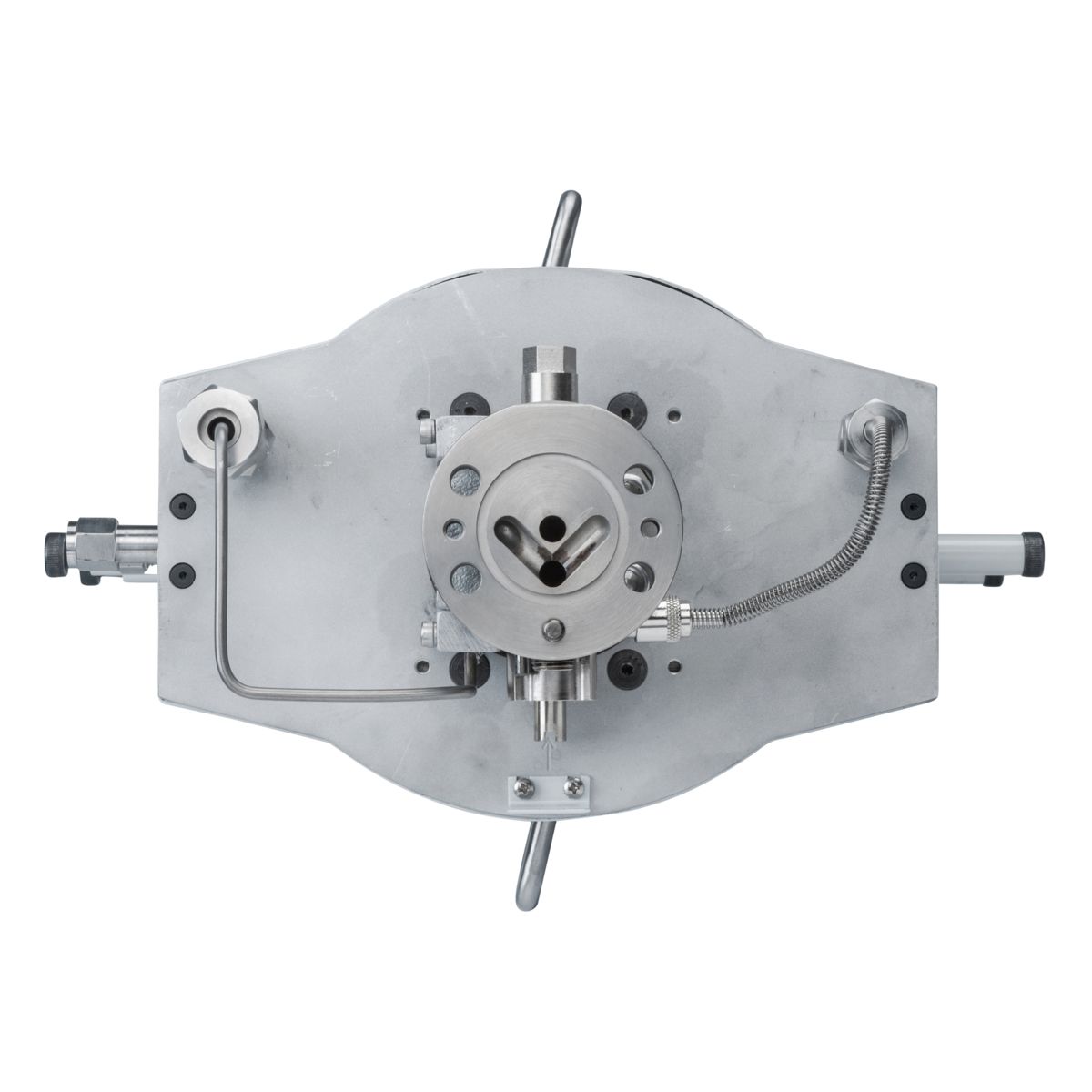

The ViscoSensor provides continuous measurements of the melt flow rate or apparent viscosity directly on the manufacturing process. The ViscoSensor system consists of two parts: a Viscosensor Rheologic Sensing Unit (RSU), connected directly to the process, and a Rheologic Control Unit that controls the ViscoSensor test parameters, provides outputs of computed results, and provides communications to an external distributed control system when required.

From breakthrough technology in the industry’s most complete line of sensors to renowned quality and performance in indicators, controls, and analytical instruments Dynisco has demonstrated the skill, experience and know-how that not only deliver the right solution for your unique application, but also provide unparalleled customer support.

General overview of what you get when you go Visco

How Dynisco is Remolding the Plastics Industry Podcast

In this episode, Microsoft's podcast hosts Deb Oberly and Dani Diaz talk with John Biagioni, President of Dynisco, who is bringing our vision of "rheology to the masses" to fruition with trailblazing cloud solutions for the plastics industry. Learn about the details of our industry and company, the surprises and insights of our journey crafting their IoT solutions, the immense value of the data we are collecting and our deliberate approach for continued success in this space.

Dynisco and Sustainability in the Plastics Industry

Sustainability is More than Protecting the Environment. Make Your Impact with Dynisco. Dynisco is dedicated to providing plastics processors and recyclers with accurate rheological information, helping to reduce waste and encourage sustainable practices

Dynisco IoT Cloud Connect: There For You 24/7 When You Can't Be

We are living in rapidly changing times. The entire world is working differently then we ever have in the history of manufacturing.Learn how the Dynisco IoT Cloud Connect and other support systems can help processors manage and monitor their production lines remotely

Dynisco Online Shop Overview

Dynisco’s Online Shop is where you can have access to ordering all Dynisco parts from Polymer Testing Equipment to Sensors to accessories- all to optimize your application.

Importance of How Online Rheometers Accurately Indicate Melt Flow Rate in an Extruder

The present work aims to describe the design of the on-line rheometer and how it can be easily connected to the extruders using existing ports and flexible adapters. It also has been explained how the proposed on-line rheometer can duplicate the test conditions of an off-line melt flow rate tester on an extruder in any compounding or manufacturing process. Furthermore, through calculation of activation energy in a specific material and introducing a temperature correlation, it has been investigated how the on-line rheometer considers the temperature dependency of material`s MFR and accurately measures this parameter at various operating temperatures.

PET and polyolefin recycling Inline viscosity measurement

Check out a recent interview with Dynisco's Johannes Lorenz where he discusses inline viscosity measurement in PET and polyolefin recycling.

Simplified Rheology for the Masses

We address issues such as the need to test polymers, the correlation of lab values to online production, and the impact of melt flow index and viscosity on part quality and profitability.

Simplified Rheology: A Technical Discussion

Understand technical aspects of how parameters change between laboratory standards and production and how advanced equipment today can adjust for these differences.

Detecting Polymers in Material Products

It can be very difficult, if not impossible, to achieve complete indentification of most polymer products. However, in most cases, this is usually not needed; what is needed is the separation, or identification, of numerous molding materials whose identity has been lost, or an indication of the type of material used to create a component.

Melt Processing of Thermoplastics for Extrusion and Injection Molding

Extrusion and injection molding are the most important conversion techniques used by the thermoplastics processing industry, Certain factors need to be considered before a thermoplastics material is processed, regardless of whether it is injection molding or extrusion molding that is used.

38 Forge Parkway,

Franklin MA 02038

+1 508 541 9400

Pfaffenstr. 21, 74078,

Heilbronn, Germany

+49 7131 297 0

Lot 3615, Jalan SM 6/8

32040 Seri Manjung, Perak, Malaysia

+605 6884014